15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

154 |

Published by VMT at Jun 29 2021

154 |

Published by VMT at Jun 29 2021

In the realm of precision engineering, brass CNC machining turning parts have become an integral component in various industries. Their exceptional durability, corrosion resistance, and malleability make them a popular choice for manufacturing intricate components. But can these brass CNC machining turning parts undergo PVD (Physical Vapor Deposition) processes to enhance their surface properties? Let's delve into the world of PVD coatings and explore their compatibility with brass CNC machining parts.

Understanding Brass CNC Machining Turning Parts

Brass, an alloy of copper and zinc, boasts remarkable mechanical properties that are well-suited for CNC machining and turning applications. Its machinability, thermal conductivity, and electrical conductivity make it a prime candidate for creating components that require both precision and functionality. Industries such as automotive, electronics, and telecommunications often rely on brass CNC machining turning parts for their diverse needs.

Many people don't know what PVD is, so our VMT engineers compiled the knowledge of brass CNC machining turning parts PVD to let everyone know about PVD. First of all, PVD we often say refers to physical vapor deposition, which uses physical processes to transfer, transfer the source to the surface of the brass custom CNC machining turned parts material, spray specific particles (high strength, wear resistance, performance, performance, corrosion resistance, etc.) to increase the material Surface characteristics.

The Intricacies of PVD Coatings

PVD, or Physical Vapor Deposition, is a surface treatment process that involves the deposition of thin films onto a substrate material. These films can impart various properties to the substrate, such as enhanced hardness, wear resistance, and aesthetic appeal. The PVD process typically takes place in a vacuum chamber, where vaporized materials are condensed onto the target surface, forming a thin yet robust coating.

Brass and PVD Compatibility

The compatibility of brass CNC machining turning parts with PVD coatings largely depends on the specific characteristics of both materials. Brass, being a metal with relatively low melting and boiling points, can be sensitive to high-temperature processes. PVD processes often involve elevated temperatures, which could potentially lead to distortion or damage to the brass substrate.

However, advancements in PVD technology have led to the development of processes that cater to temperature-sensitive materials like brass. By carefully controlling the deposition parameters, such as temperature and deposition rate, it is possible to apply PVD coatings onto brass without compromising its structural integrity.

Advantages of PVD-Coated Brass CNC Machining Turning Parts

When successful, the addition of PVD coatings to brass CNC machining turning parts can yield several advantages. These include:

Enhanced Hardness and Wear Resistance

PVD coatings can significantly increase the surface hardness of brass parts, making them more resistant to wear, abrasion, and impact. This is particularly beneficial in applications where the components are subjected to friction and mechanical stress.

Corrosion Protection

Brass is naturally corrosion-resistant due to its copper content, but a PVD coating can provide an additional layer of protection against harsh environments. The coating acts as a barrier, preventing corrosive agents from reaching the underlying brass substrate.

Aesthetic Appeal

PVD coatings offer a range of color options, allowing manufacturers to customize the appearance of brass CNC machining turning parts. This is especially valuable in industries where visual aesthetics play a vital role in the overall product design.

Factors to Consider

Before subjecting brass CNC machining turning parts to PVD processes, it's essential to consider a few critical factors:

Temperature Sensitivity

As mentioned earlier, the temperature sensitivity of brass must be carefully considered. Optimal PVD process parameters should be chosen to prevent thermal damage to the substrate.

Coating Adhesion

Ensuring strong adhesion between the PVD coating and the brass substrate is crucial for the long-term performance of the coated parts. Proper surface preparation and cleaning are essential to achieve reliable adhesion.

Post-Coating Machining

In some cases, post-coating machining may be necessary to achieve tight tolerances or specific geometries. The effects of post-coating machining on the PVD-coated brass parts should be evaluated to avoid compromising the coating's integrity.

Brass CNC machining turning parts PVD (Physical Vapor Deposition) technology is divided into three categories: vacuum evaporation coating, vacuum sputtering coating and vacuum ion coating. Compared with the three major types of PVD technology, the corresponding vacuum coating equipment includes vacuum evaporation coating machine, vacuum sputtering coating machine and vacuum ion coating machine. In the past ten years, vacuum ion plating technology has developed the fastest and has become one of the most advanced surface treatment methods. What we usually call brass CNC machining turning parts PVD coating refers to vacuum ion coating; the commonly referred to PVD coating machine refers to vacuum ion coating machine.

The application of brass CNC machining turning parts PVD coating technology is mainly divided into two categories: decorative plating and tool plating.

Mainly used in various fields of the hardware industry, such as brass CNC machining turning parts, door and window hardware, locks, bathroom hardware and other industries.

The purpose of tool plating is to improve the surface hardness and wear resistance of the brass CNC machining turning parts, reduce the friction coefficient of the surface, and increase the service life of the workpiece;

Mainly used for various brass CNC machining turning parts tools (such as turning tools, planers, milling cutters, drills, etc.) and other products. It is an environmentally friendly surface treatment method that can truly obtain micron-level pollution-free coatings. Various single metal films (such as aluminum, titanium, zirconium, chromium, etc.), nitride films (TiN [titanium gold], ZrN (zirconium gold), CrN, TiAlN) and carbide films (TiC, TiCN) can be prepared, and Oxide film (such as TiO, etc.). It is a very cost-effective surface treatment method, so PVD technology has developed rapidly in recent years.

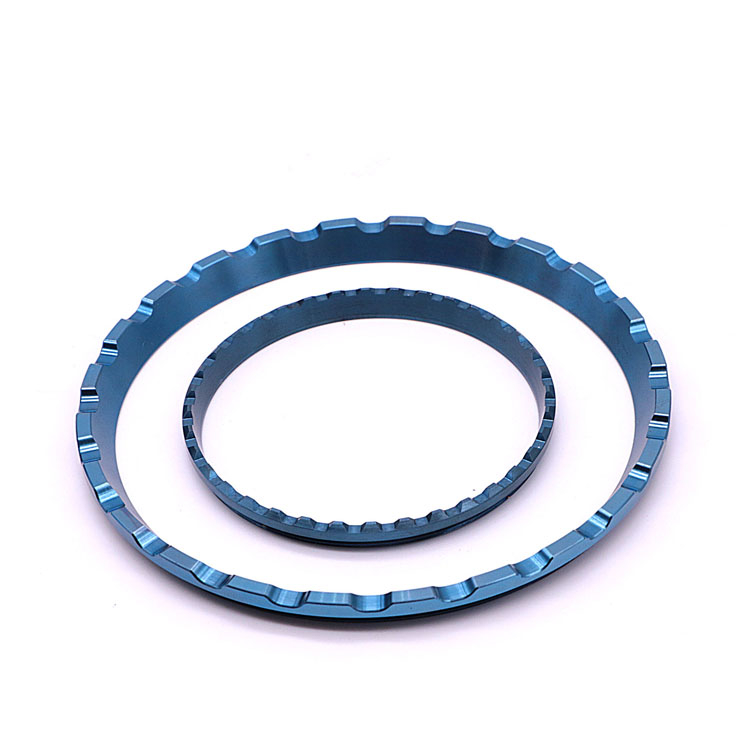

Brass CNC machining turning parts adopts PVD coating technology to coat the film with high hardness, high wear resistance (low friction coefficient), good corrosion resistance and chemical stability, etc., and the film has a longer life; at the same time, the film can Greatly improve the appearance and decorative performance of the workpiece.

Material application PVD film can be directly plated on stainless steel and cemented carbide、Brass CNC machining turning parts, but for zinc alloy, copper, iron and other die-casting parts, it is advisable to conduct chemical chromium plating before PVD plating. PVD can be plated with gold, brass, rose gold, silver white, black, smoky gray, copper, brown, purple, blue, wine red, bronze and other colors, and can provide the required color and quality.

Of course, in the production process, we are more concerned about the Brass CNC machining turning parts price issue. Although the use of PVD coating technology can produce high-quality coatings, the cost of the PVD coating process is actually not high. If the appearance requirements are Brass turning parts relatively high, sandblasting should be carried out before electroplating. According to the appearance grade, select the appropriate sand type, and cover the defects such as knives, bumps and scratches caused by the previous process with sand to achieve the lowest cost. Products that meet the requirements.

The above is the knowledge points of Brass CNC machining turning parts PVD. VMT has many friends with strong PVD technology who have cooperated for more than ten years. They can quickly cooperate with the production of color samples and rapid mass production delivery. For more detailed information, please contact VMT precision metal parts machining manufacturer.

Conclusion

In the ever-evolving landscape of precision engineering, the question of whether brass CNC machining turning parts can undergo PVD processes is met with both possibilities and challenges. With advancements in PVD technology, it's becoming increasingly feasible to apply durable and functional coatings to brass substrates. Careful consideration of material compatibility, process parameters, and desired outcomes is essential to harness the benefits of PVD-coated brass CNC machining turning parts effectively.

FAQs

Can PVD coatings be applied to other metals besides brass?

Absolutely. PVD coatings can be applied to a wide range of materials, including stainless steel, titanium, and aluminum.

Are PVD-coated parts suitable for high-temperature applications?

Yes, certain PVD coatings are designed to withstand elevated temperatures, making them suitable for high-temperature applications.

What industries commonly use PVD-coated brass parts?

Industries such as aerospace, electronics, and medical devices often utilize PVD-coated brass parts for their combination of functionality and aesthetics.

Can PVD coatings be removed or recoated?

In some cases, PVD coatings can be removed using specialized processes. Recoating may also be possible, depending on the condition of the substrate and the desired outcome.

How does PVD compare to other surface coating methods?

PVD offers advantages like precise control over coating thickness and composition, as well as the ability to coat complex geometries, setting it apart from other coating methods.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!